| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : GENERTEC

Model Number : MGK7363

MOQ : 1

Price : Negotiable

Payment Terms : L/C,D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : Peak Season Lead Time: 1-3 months, Off Season Lead Time: 1-3 months

Delivery Time : 8-8 workdays

Packaging Details : Standard Export Plywood Case or Carton

Worktable diamete : 630 mm

Worktable adjustable angle : ±3°

Worktable rotations : 15~ 100 rpm

Lengthwise moving speed of saddle : 0.1 ~ 2.0 m/min

Lengthwise moving travel of saddle : 350 mm

Workpiece roughness : Ra ≦0.16 μm

Table planeness : 630 :0.003 mm

The wheel head vertical travel : 325 mm

Totol power : 10.9 kw

Machine weight : 4000 kg

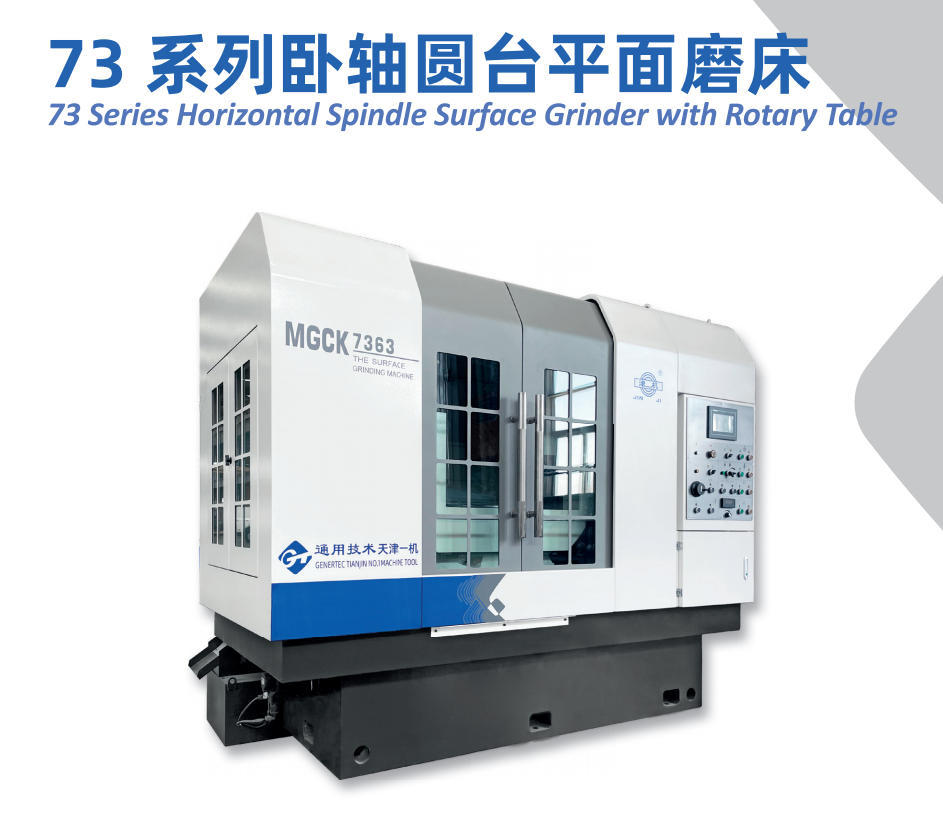

MGK7363 High-precision CNC Horizontal Spindle Rotary Table Surface Grinding Machine

The MGK7363 high - precision CNC horizontal spindle rotary table surface grinding machine is a precision processing equipment that uses the periphery of the grinding wheel to grind metal materials. It can process the plane of workpieces with a diameter less than φ630mm and high requirements for flatness and surface roughness. The flatness of the workpiece plane can reach 0.003mm, and the surface roughness Ra value is not greater than 0.08μm. The worktable and the longitudinal movement (X - axis) of the bed and the vertical movement (Y - axis) of the grinding head, these two coordinate axes, both adopt ball screw transmission driven by AC servo motors. The Y - axis is also equipped with a linear encoder to form a closed - loop system, with sensitive feeding and reliable positioning. The function of CNC axis linkage can be used to grind inner and outer conical surfaces.

| Series 73 Horizontal Spindle Rotary Table Surface Grinding Machines. This type of machine tool uses the periphery of the grinding wheel to grind the horizontal surface of the workpiece. The worktable can be adjusted in angle and rotated ±3° - 10° around the horizontal axis, and can grind the inner and outer conical surfaces of the workpiece. This type of machine tool has relatively high machining accuracy, surface roughness, and production efficiency. For models with a worktable diameter ranging from Φ400mm to Φ3500mm, it is suitable for the machining of disc - shaped cutters, piston rings, friction plates, bearing rings, gears after angle adjustment, and the repair and fitting of various planar parts. High - precision models can also meet the grinding processing requirements of high - precision annular components for aviation use. |  |

|  |  |

Main Technical Specifications

Size of the worktable working surface ……………………………………… φ630 mm

Maximum height of the workable workpiece ………………………………… 250 mm

Maximum longitudinal travel of the carriage ……………………………… 400 mm

Rotational speed of the worktable (stepless speed regulation) ………………… 20—100 r/min

Size of the grinding wheel (outer diameter × width × inner diameter) …………… φ400×40×φ127 mm

Rotational speed of the main shaft ………………………………………… 1440 r/min

Distance from the center line of the main shaft to the worktable surface ………… 125 - 450 mm

Longitudinal moving speed of the carriage (X-axis, stepless speed regulation) ……… 50 - 2000 mm/min

Vertical moving speed of the grinding head (Y-axis, stepless speed regulation) ……… 10 - 500 mm/min

Vertical micro-feed amount of the grinding head …………………………… 0.001 mm

Longitudinal micro-feed amount of the carriage ……………………………… 0.001 mm

Grinding wheel spindle motor: 7.5 KW, 1440 r/min

AC servo motor for longitudinal movement of the worktable: Torque 11 N·M, Rotational speed 3000 r/min

AC servo motor for vertical movement of the grinding head: Torque 6 N·M, Rotational speed 3000 r/min

Gear reduction motor of the worktable: Power 1.5 KW, Rotational speed 1400 r/min

Motor of the lubricating oil pump for the hydrostatic grinding head: Power 0.55 KW, Rotational speed 1400 r/min

Motor of the lubricating oil pump for the bed guideway: Power 0.55 KW, Rotational speed 1400 r/min

Overall dimensions of the machine tool (length × width × height) …………… 2550×1780×2100 mm

Weight of the machine tool (net weight/gross weight) ……………………… 5000/5200 Kg

Main Specifications

| Items | Unit | MG7340/1 | MGCK7340 |

| Worktable diameter | mm | 400 | 400 |

| Worktable adjustable angle | | ±10° | ±10° |

| Worktable rotation | rpm | 60 ~ 140 | 60 ~ 160 |

| Lengthwise moving speed of saddle | m/min | 0.05 ~ 2.5 | 0.1 ~ 2.5 |

| Lengthwise moving travel of saddle | mm | 240 | 240 |

| Workpiece roughness | μm | Ra ≤ 0.08 | Ra ≤ 0.16 |

| Table planeness | mm | 400: 0.003 | 400: 0.003 |

| The wheel head vertical travel | mm | 170 | 190 |

| Total power | kw | 8.32 | 10.07 |

| Machine Weight | kg | 2800 | 2800 |

| Items | Unit | MGCK7363 | MGK7363 | MGK73100/3 |

| Worktable diameter | mm | 630 | 630 | 1000 |

| Worktable adjustable angle | | ±3° | - | ±3° |

| Worktable rotations | rpm | 15 ~ 100 | 20 ~ 100 | 8 ~ 48 |

| Lengthwise moving speed of saddle | m/min | 0.1 ~ 2.0 | 0.05 ~ 2.0 | 0.1 ~ 2.0 |

| Lengthwise moving travel of saddle | mm | 350 | 350 | 650 |

| Workpiece roughness | μm | Ra ≤ 0.16 | Ra≤ 0.08 | Ra ≤0.16 |

| Table planeness | mm | 630 : 0.003 | 630 : 0.003 | 1000 : 0.005 |

| The wheel head vertical travel | mm | 325 | 325 | 500 |

| Total power | kW | 10.9 | 13.8 | 22 |

| Machine Weight | kg | 4000 | 4000 | 14800 |

Company Profile

|

Genertec Tianjin No.1 Machine Tool Co., Ltd. belongs to China General Technology Group, a central enterprise.

The company was formerly known as Tianiin No.1 Machine Tool Works, one of the 18 Lohans enterprises in themachine tool industry in the early days of the founding of New China, and Tianjin Jinyi Grinding Machine Co., Ltd. ithas accumulated more than 70 years of history in the gear machine tool and grinder industry, and is the backboneenterprise in China's machine tool manufacturing industry.

|  |

| Why Choose Us? The company focuses on developing extended products in the industrial chain such as gear machining machines, special grinding machines, and precision transmission devices, and provides customers with professional comprehensive solutions for gear machining. The products are sold in 30 provinces, municipalities directly under the Central Government, and autonomous regions in China, and are exported to more than 20 countries including Germany, Spain, the United States, Sweden, Brazil, Japan, and India. It is a backbone manufacturer in China for producing complete sets of machining machines for spiral bevel gears. The company has world-class high-end precision machining and testing equipment, and an experienced R & D team and a main production force, and has passed the ISO 9001 quality management system certification. | Other Products The leading products include: 18 major categories and more than 30 series of products such as CNC gear shapers, gear milling machines, gear broaching machines, gear grinders, gear shapers, gear lapping machines, and complete sets of bevel gear machining equipment; as well as 6 series of products including horizontal-spindle rectangular-table surface grinders, horizontal-spindle rotary-table surface grinders, vertical-spindle rotary-table surface grinders, CNC form grinders, floor-type guideway grinders, and high-precision CNC grinding centers. |

FAQ

|

|

73 Series Horizontal Spindle surface Grinder with Rotary Table Images |